Insulating & Metal Clad Piping

Why Insulate?

There are many reasons, but usually the number one reason is energy conservation. The following is a partial list of more reasons to insulate.

- → Protect equipment

- → Freeze protection

- → Prevent condensation

- → Maintain and withstand high temperatures

- → Reduce greenhouse gas emissions

- → Improve process control and efficiency

- → Reduce surface temperature for personnel protection

At Border Insulators, we use a variety of insulating materials in sizes ranging from 1" - 20".

Mineral wool fiber

This is the most common type used. It is made of inorganic mineral fiber and is used on all types of piping and vessels and is

a non-combustible product with a melting point of approximately 2150° F.

(1177° C), giving it excellent fire resistant properties. Mineral wool is a water repellent yet vapor permeable material.

This is the most common type used. It is made of inorganic mineral fiber and is used on all types of piping and vessels and is

a non-combustible product with a melting point of approximately 2150° F.

(1177° C), giving it excellent fire resistant properties. Mineral wool is a water repellent yet vapor permeable material.

Calcium silicate

Calcium Silicate is a granular insulation made of lime and silica, reinforced with organic and inorganic fibers molded into rigid forms.

This product is used for insulation up to 1200° F (650° C). It is a high temperature pipe and block insulation with superior durability,

resistant to fungi and is non - combustible.

Calcium Silicate is a granular insulation made of lime and silica, reinforced with organic and inorganic fibers molded into rigid forms.

This product is used for insulation up to 1200° F (650° C). It is a high temperature pipe and block insulation with superior durability,

resistant to fungi and is non - combustible.

Fiberglass Insulation

Fiberglass Insulation is made from rotary glass fibers bonded with a thermo-setting resin. It is suitable for installation over hot,

cold, concealed and exposed piping systems with operating temperatures up to 1200° F (650° C).

Fiberglass Insulation is made from rotary glass fibers bonded with a thermo-setting resin. It is suitable for installation over hot,

cold, concealed and exposed piping systems with operating temperatures up to 1200° F (650° C).

Aluminium Jacketing(metal cladding)

We use a variety of different products ranging from aluminium jacketing with waterproofing membrane and canvas/fire protection, and PVC jacketing.

We use a variety of different products ranging from aluminium jacketing with waterproofing membrane and canvas/fire protection, and PVC jacketing.

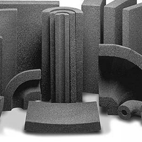

Foam Glass

Foam Glass insulation is what we use in all of our refrigeration projects. The Foam Glass insulation keeps the moisture off of pipe to prevent corrosion.

Foam Glass insulation is what we use in all of our refrigeration projects. The Foam Glass insulation keeps the moisture off of pipe to prevent corrosion.